- Trends in Mine Maintenance Technology

- Strategies to overcome 2023 onsite maintenance issues

- Case Study: Asset management versus mine maintenance

- Holistic fixed and mobile plant asset maintenance

- Operational readiness and alignment with ISO 55001?

- Benefits of cross collaboration in Root Cause analysis of safety incidents and equipment failures

- Case study: Diversity and inclusion in mine maintenance

- Case Study – “Revolutionizing Mining: Harnessing AI, IoT, and MachineLearning to Power Tomorrow’s Mines”

- Improving safety and skills training with 3D immersive tech – AR, VR & digital twin development

- Latest developments in Automation and robotics

- Getting on top of data analytics and management

- Lifecycle planning techniques to increase total operation profitability

- Bulk handing equipment – replacement versus refurbishment

- Impact of meeting ESG requirements and net zero targets on mine maintenance practice

- Importance of extreme weather risk planning in asset management and reliability

- Building successful OEM relationships in challenging times

- Effective scheduling and inventory control in challenging times

- Procurement – rising costs, supply chain delays, spare part availability, esg aware procurement

- Meeting OH&S standards and statutory compliance requirements of physical assets

- Case Study: Specific maintenance issues impacting underground mining

Delegate Registration & Coffee

During this presentation, Nieresh will delve into the critical aspects of Maintenance Strategy and Risk, exploring how effective maintenance practices can mitigate downtime and optimize performance in various industries. He will start by discussing the importance of proactive maintenance in identifying and mitigating potential risks, ultimately minimizing unplanned downtime and its associated costs. He will then delve into different maintenance strategies, such as preventive, predictive, and condition-based maintenance, and highlight their significance in risk management

NIERESH JEYARAJAKUMAR

Snr Reliability Engineer, Holistic asset Management

Part 1: Understanding ESG in Metals and Mining

• What ESG means in the context of the metals and mining sector.

• Specific challenges and opportunities within this industry

• Key ESG factors that are most relevant and material for asset managers in metals and mining.

Part 2: Why ESG Integration Matters

• Benefits of incorporating ESG considerations into asset management strategies.

• Benefits of incorporating ESG considerations into asset management strategies.

Part 3: Best Practices and Case Studies of Nickel Industries Limited

• The company’s ESG approach

• Success stories and recent achievements

MUCHTAZAR

Sustainability Manager, Nickel Mines, Indonesia

10:30 Morning Coffee & Networking

• What is asset management?

• Ensuring the selection of the right assets

• Maintenance – an essential part of asset management

• Putting it all together – a framework for effective asset management

NORM DOXAMAKIS

Maintenance and Engineering Manager, Dugald River Mine, MMG

- Shutdown management lacks discipline

- No scope lock down, or emergent work approvals

- No regular monitoring or control

- Roles and responsibilities unclear discipline

- Spares unavailable or arrive too late

- Contractor mgmt. is adhoc

- Project mgmt./delivery is disjointed and regularly underspent for the year

- No gated approval process

- No oversight of capital porfolio at Mgmt. level

- Projects regularly overrun on time and funds

- Work Mgmt. processes are poorly executed or understood leading to a highly reactive maintenance program

- No sustainable processes to ensure repeatable outcomes and integration into annual Business Planning processes

- How does a plant improvement initiative

make it into the 5-year budget? - No Life Cycle Plans or Whole of Life plans for critical assets

- How does a plant improvement initiative

- Depts are siloed with poor Operating Discipline and limited integration across the site

BRENDAN DAY

Principal Asset Management Consultant, Xenco

It is an established fact that Operational Readiness is critical to the success of any project, as it directly addresses the operational requirements necessary for a smooth transition from project to operations. By focusing on Operational Readiness, the risk of project delays during commissioning and handover is significantly reduced. It is also known that Operational Readiness plays a pivotal role in ensuring business continuity during operations.

However, despite budget allocation and expenditure on Operational Readiness, some projects still fail to achieve these crucial goals. Consequently, they face cost overruns, extensive delays, and increased business risk due to rejections or disruptions caused by the lack of essential information, spare parts, or project-specific knowledge. To combat these challenges, this session offers practical tools that have been tested and proven effective in numerous projects undertaken by leading mining organisations.

These tools have successfully enhanced the operational readiness of projects ranging from a modest $0.2M to a staggering +$4,000M in cost.

Attendees can expect to gain invaluable insights, strategies, and techniques that will undoubtedly improve the operational readiness of their respective projects.

DANIEL RIVERIA

Asset Management Consultant, Coach, Mentor at Lead Asset Management

• Sourcing from global ethical suppliers

• Ensuring machinery/equipment is environmentally friendly and durable/reliable & safe

ANDRES ARROYO

Procurement Project Specialist, Rio Tinto

1:40 Lunch

MICHAEL POPE

Planner/Co-ordinator, Queensland Alumina

• How can we attract and retain a diverse workforce in maintenance?

• What role can maintenance teams play in promoting DEI throughout the organisation?

• How can we create a culture of inclusion where all employees feel valued and respected?

STEVEN ASNICAR

CEO, Diversity Australia

15:50 Afternoon Tea and Networking

• Exploring your responsibilities in Psychosocial Risk Management

• Master of a Psychosocial Risk Management Framework for the workplace

• Initiating Practical Measures for Immediate Action

NAOMI ARMITAGE

Director, Humanology Group

• Impact on asset management and maintenance activities

• Skilled staff shortages

• OEM relationships

• Budgetary constraints

• Meeting regulatory obligations

1 Hour Networking drinks

Delegate Registration & Coffee

Integrating asset management across the mine site is often challenging for maintenance managers and often fails to deliver long term benefits. In this session, Matt will discuss the key areas across the business cycle and operating system that are essential to achieve successful asset management integration -

• Aligning the objectives of asset management, and sustainable, safe production

• Assessing the impact of asset management on the mining value chain

• Integration into the planning cycle

• Winning support for sustaining capital to deliver business improvement in asset management

• Delivering outcomes through the operating system and consistent work disciplines

MATT COLQUHOUN

Director - Infrastructure, Assets & Places, KPMG Australia

As our assets, markets, and society at large evolves throughout the various lifecycles, so should the strategies which we use to govern their management. As physical assets are not static or inanimate objects that remain the same for their life, nor should be the strategies that we refer to that determine the care we provide.

Operational readiness programs that are now in place with many mature organisations allow the development of strategies that are fit-for-purpose at the point when the asset is commissioned and started up for the first time, but they aren’t evergreen.

This presentation highlights the next stage of the maturity journey, where firms should build up their systems so that their asset management strategies evolve with asset

ageing.

Regulations, risk tolerance, and economic models all evolve. Therefore, the relative criticalities are not stationary from both a process safety and a reliability

standpoint. They should modify to reflect these modifications, as should the maintenance tactics they promote.

This presentation reviews established best practices and presents a framework for asset management techniques to stay current and optimal throughout an asset's lifespan in light of its current status, aiming for ‘evergreen’ asset strategies.

ERIC VANDENBERG

Operations Manager, Verbrec Asset Management

10:30 Morning Coffee break & Networking

At many existing bulk material handling facilities, equipment such as stackers, reclaimers and ore car dumpers are nearing the end of their design lives. Owners are faced with the decision on whether to refurbish existing or procure replacement machines. There are also continuing pressures for increased throughput and in the case of ports, to accept larger ships.

Traditionally, owners would carry out a refurbishment to allow the life of their equipment to be extended. However, due to the continuing strong demand for commodity exports and high equipment utilisation levels, downtime is critical. Thus, decisions between refurbishment and replacement equipment can have a big impact on plant availability, cost and revenue. Richard will talk about how ASPEC has developed a program called FULS (fatigue useful life simulation) to assist owners making decisions on when to carry out machine replacement or major refurbishment.

RICHARD MORGAN

Director, Aspec Consulting

12:30 MORNING COFFEE & NETWORKING

"In an era of profound technological change, the mining sector is on the cusp of a digital revolution. This engaging and insightful talk will delve into how Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning are shaping the future of the mining industry. We will explore the potential of these digital tools in optimizing operational efficiencies, enhancing safety protocols, predicting maintenance, and facilitating informed decision-making. Whether it's AI-assisted mineral prospecting, IoT-enabled real-time monitoring, or Machine Learning models for predictive maintenance, these technologies are transforming the way we mine and manage resources. Join Ali as he unearths the digital future of mining and its implications on sustainability, productivity, and safety."

ALI SOOFASTAEI

Artificial Intelligence Program Leader, Vale

JOE CRONIN

CEO, Australian robotics and droids

JAMES LITJENS

Director, Emerging Technologies, ARQ Group

13:40 Lunch Break & Networking

BURCIN OXTURK

Leader, Asset Management and

Digital Technology, Business Management, Glencore

• Existing continuous monitoring challenges on large medium voltage networks

• Taking advantage of the physical principles to simplify the monitoring system requirements

• How AI is helping us in processing large amount of data point

• Real live example

Description:

“Online continuous monitoring of large medium voltage networks has always been a challenge due to the

substantial hardware requirements and the complexity in analysing and utilizing the collected data

In this session, Machinemonitor will unveil a solution designed to revolutionize the screening and assessment

process for large industrial facilities.

This solution aims to be the day to day tools for asset managers, allowing them to visualize the condition of

their plant, investigate developing failure mechanisms within the assets and get expert engineers maintenance

recommendations, ultimately improving efficiency, reducing downtime and increasing reliability.”

16:00 Afternoon tea and Networking

GOPI CHATTOPADHYAY

Post Graduate Program Co-ordinator,

Maintenance and Reliability, Federation University

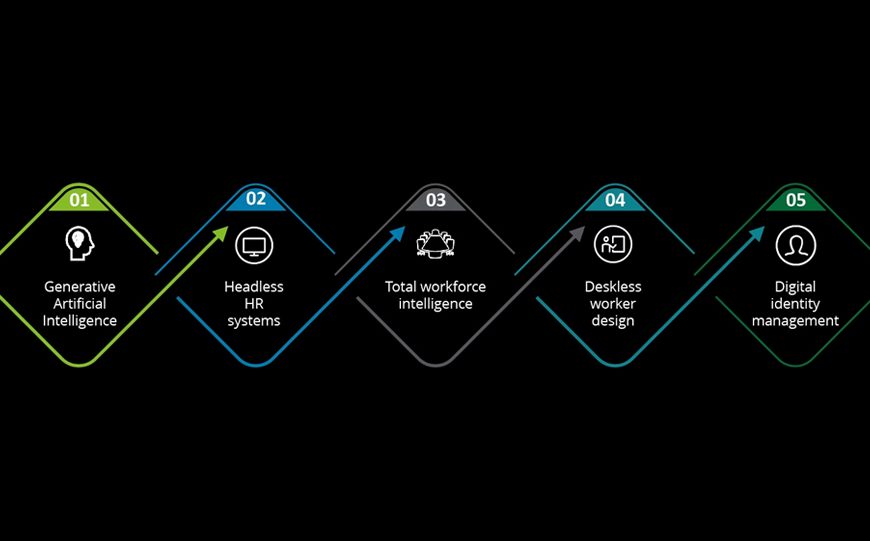

• Impact of ChatGPT and AI

• Future Workforce

• Ethical considerations

• Reliability and safety impacts

17:00 Closing remarks from the Chair

18:00 End of Conference

Reducing Risk at the Lowest Possible Cost – aligning your MRO Supply Chain with your Asset Management

Strategy

9:00- 12:30pm

Outline: Too many businesses either spend too much on their MRO materials or not enough. This results in either excessive cost or increase risk or both! This workshop will help you map your asset management maturity and then how to align your MRO Supply Chain.

• Material Criticality Calculation

• Min/Max or Reorder Point / Reorder Quantity Calculation

• Importance of Lead Times

• KPI’s and Metrics

• It’s all about PEOPLE and PARTS, we will help you manage the Parts to make your People more effective and productive.

• Managing your MRO can save you A LOT of pain (cost & stress) when well-managed, let’s map out where you stand and start moving forward.

1:30 – 5:00pm

A workshop on how to identify and implement asset and maintenance strategies in the mining industry is essential for optimizing the efficiency and reliability of mining operations. Here is an outline of the key topics and activities you can include in such a workshop:

• Asset Life Cycle Management

• Risk Assessment and Mitigation Maintenance Strategies

• Maintenance Strategies Overview

• Reliability Centered Maintenance (RCM)

• Predictive Maintenance Techniques

• Developing Maintenance Plans Implementation and Case Studies

• Implementing Asset and Maintenance Strategies

• Case Studies and Best Practices

• Workshop Exercises and Group Discussions

Register & pay for 3 delegates & get 3 tickets free

Register & Pay for 3 Delegates & get 3 FREE TICKETS ( SAVE 50% COST)

Click on the button below and fill the form to confirm your registration.

This site uses cookies. Find out more about cookies and how you can refuse them.