2025

MINE MAINTENANCE 2025Mine Maintenance, Asset Management & Reliability Strategies 2025 Conference

28th-29th August, Novotel Perth

Days

Hours

Minutes

Seconds

Sponsorship & Speaking Opportunites:

Mine Maintenance, Asset Management & Reliability 2025 Forum offers sponsors an excellent opportunity to demonstrate thought-leadership and leverage networking opportunities to build brand-value amongst your target audience. If you would like to know more about sponsorship, exhibition and business development opportunities please just get in touch with us – sponsorship@ibrc.com.au

Early Invited Speakers include:

Speakers of the MINE MAINTENANCE 2025 Mine Maintenance, Asset Management & Reliability Strategies 2025 Conference

Get Involved

Interested to be a sponsorer/speaker for this event?

Become a Sponsor

Speak at this event

MINE MAINTENANCE 2025 Schedule

Learn schedule, program and topics of the MINE MAINTENANCE 2025 Mine Maintenance, Asset Management & Reliability Strategies 2025 Conference

Conference Resource

Download a copy of the event brochure and know more about the venue.

Download Brochure

Registation Packages

Learn about registation Prices and offers for the Mine Maintenance 2025- Mine Maintenance, Asset Management & Reliability Strategies 2025 Conference

Click on the button below and fill the form to confirm your registration.

Latest Posts

You can find the latest posts in this section.

Asset owners integrating artificial intelligence (AI) models into their workplaces and processes need to carefully consider the issue of potential harm – to employees, fund members and society generally – and the guardrails that are necessary to minimise unforeseen consequences...

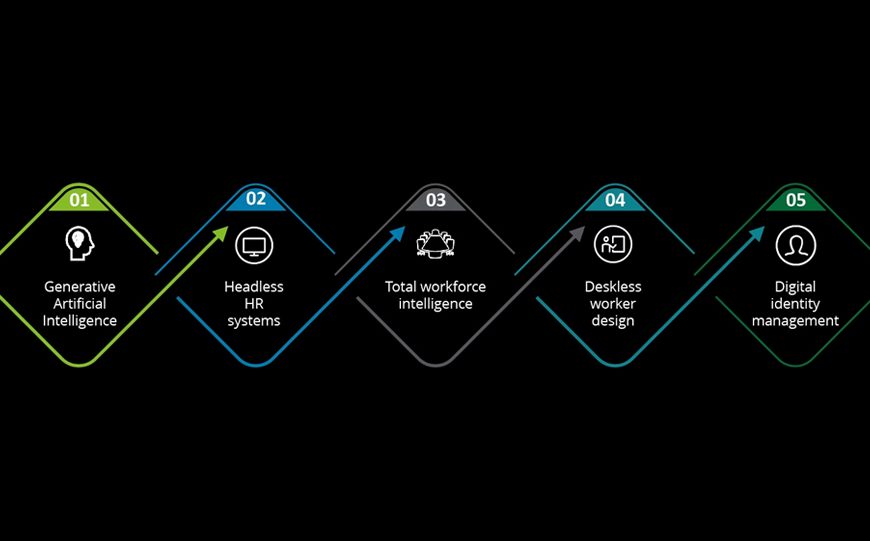

Authored by Franz Gilbert, Matthew Shannon, and Erin Spencer Deloitte’s Human Capital Forward team predicts how five of today’s HR technology trends could innovate across disparate systems, work processes, and workforce experiences in 2024. Technology never fails to innovate. Across...

The Australian Government has today released the Data and Digital Government Strategy (the Strategy), setting a clear vision for delivering simple, secure and connected public services, for all people and business, through world class data and digital capabilities. This is...

With so many superannuation funds to choose from, working out which one is the best fit for your retirement savings can be confusing. TelstraSuper CEO Chris Davies offers some suggestions for how to get the most from your super fund....

Contact Us

Contact us to know more about this Conference

This site uses cookies. Find out more about cookies and how you can refuse them.